In a city recovering from an earthquake disaster a group of men have taken upon themselves to manufacture an as of yet unheard of creation.

Using cardboard, they have made a Lamborghini, coining the name Damborghini from the word “damboru” meaning cardboard in Japanese.

Behind this play on words is a dream given shape and the hope to inspire once again the place they call home.

Continuing after the debut of the first generation in 2015, in the pursuit of getting ever closer to the genuine article, without compromise on any detail, they have now completed car #2.

Ishinomaki’s dream is now in its 2nd chapter!

Konno Konpou Inc. was founded in 1973 in Miyagi Prefecture’s Ishinomaki City. The company started out as a packaging company that used wooden pallets and boxes, however the 3rd generation CEO, Hideki Konno, saw the future and resource saving potential the much lighter than wood corrugated cardboard had to offer.

Konno Konpou Inc. was founded in 1973 in Miyagi Prefecture’s Ishinomaki City. The company started out as a packaging company that used wooden pallets and boxes, however the 3rd generation CEO, Hideki Konno, saw the future and resource saving potential the much lighter than wood corrugated cardboard had to offer.

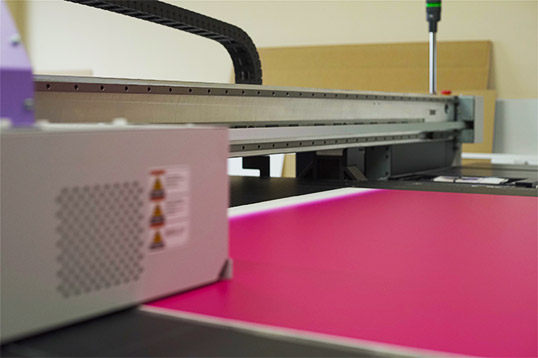

Tri-wall corrugate boxes, developed in the U.S., have a triple layer design that makes it the ultimate in strength and water resistant cardboard. Deeply impressed with this material which up to that point had not been used in the Tohoku region of Japan, Konno made a large investment into manufacturing facilities. Drawing much appeal from the U.S. based Tri Wall Containers company in 2005 he became the first authorized reseller for the Tohoku and Hokkaido regions of Japan.

However, the operation had to be started from scratch and without any purchase orders at all. Konno and a handful of his employees then took it upon themselves to test produce corrugated cardboard made modeled objects and furniture in a corner of the plant. In the spirit of true artisans, the workers mastered CAD software along with cutting machines and began creating one intriguing design after another from a single piece of cardboard. Among those items, during the bankruptcy of Lehman Brothers when work was scarce, they reproduced a 3m tall version of a Gundam robot in astounding quality.

After continual hard fought sales work, packaging work soon began to roll in. Meanwhile as a nonprofit disaster countermeasure Konno, who was concerned with preparing for large Miyagiken-oki earthquakes, began making room partitions and temporary furniture out of corrugated cardboard as well as going around to local government agencies advising on their utilization and storage.

After continual hard fought sales work, packaging work soon began to roll in. Meanwhile as a nonprofit disaster countermeasure Konno, who was concerned with preparing for large Miyagiken-oki earthquakes, began making room partitions and temporary furniture out of corrugated cardboard as well as going around to local government agencies advising on their utilization and storage.

「I was working frantically always on the move without thought for my family. There’s no point in investing in something you can do from the beginning yourself. I’m beginning something nobody else has ever done and creating its own market!」

Centered on Konno and his policy all of his employees are united and pushing forward with their concept. The corrugated cardboard business gradually began to get on track and the company started to pay off the loans that were taken out. That’s when the arrow that was March 11th struck the country.

At the time of the disaster Konno was in Tokyo for work. Feeling the strong shock, he instantly checked his cellphone to find the epicenter of the quake. It was Sanrikuoki. “The tsunami was going to hit Ishinomaki as well.” Konno’s intuition told him as much and he began calling his family and company again and again. However, the call was never received.

At the time of the disaster Konno was in Tokyo for work. Feeling the strong shock, he instantly checked his cellphone to find the epicenter of the quake. It was Sanrikuoki. “The tsunami was going to hit Ishinomaki as well.” Konno’s intuition told him as much and he began calling his family and company again and again. However, the call was never received. Amid the anxiety and confusion, he found refuge at a nearby hotel and could do nothing but watch the hell and destruction wrought by the tsunami unfold across Tohoku on the T.V.

After 2 days he arrived home in Ishinomaki and luckily found his family and employees safe. Although the area was not hit directly by the tsunami his home was destroyed and his company suffered damage. Although Ishinomaki turned out to be the most heavily damaged area it is where he makes his living. He had no choice but to press on. While taking on another loan Konno was determined to rebuild his company.

Receiving support from across the country Ishinomaki began on the road to reconstruction and restoration. However, the local youth, as they did before the disaster, continued to leave their city behind them, going out of prefecture to continue their education and search for employment. Why is that? The youth were not to blame and Konno knew it.

Receiving support from across the country Ishinomaki began on the road to reconstruction and restoration. However, the local youth, as they did before the disaster, continued to leave their city behind them, going out of prefecture to continue their education and search for employment. Why is that? The youth were not to blame and Konno knew it. “We are the ones who haven’t shown them the dream for our city. We can’t be tired out and lose inspiration in our daily work and lives.” He then found the answer and decided to let his dreams and admiration take physical form. From a young age he greatly admired Lamborghinis. This was the start of Konno’s idea to use corrugated cardboard to build his Damborghini.

They had no actual Lamborghini on hand so they decided to draw up original designs from available pictures of the car. This time Konno decided to not take the lead. He set his mind to creating a work environment where his employees could freely work on the project between completing their daily tasks.

They had no actual Lamborghini on hand so they decided to draw up original designs from available pictures of the car. This time Konno decided to not take the lead. He set his mind to creating a work environment where his employees could freely work on the project between completing their daily tasks. His employees rose to the occasion and began prototyping a 1/2 scale model to start with. The prototype completed in 2014 was an article of excellent workmanship. Confident it could be done, Konno gave the go-ahead for production of a full-size model.

The actual production was a series of trial and error. Corrugated cardboard is fundamentally a flat surface. The problem was how much to cut the surface of the cardboard to recreate the smooth lines and curves of the car. The most difficult part was the design of the tires. As a matter of course the shape along with each groove and detail put into the foil brought the creation closer and closer to the genuine article. Although most of these details are hidden on the body of the car the thorough commitment to detail enhances the car’s almost supernatural overall feeling of completion.

The announcement of the Damborghini in 2015 stirred up a sensation beyond all expectations. Visitors and media from around the country rushed in to see the creation. A number of proposals for support and business partnerships began flowing in.

Just at that time in Onagawa, an adjacent town to Ishinomaki, reconstruction plans were underway along with the building of a new shopping center and the governor who was a fellow high school classmate of Konno’s opened up a branch shop for Konno there. At the end of 2015 on a corner of the shopping center they opened a showroom which doubles as a store.

Just at that time in Onagawa, an adjacent town to Ishinomaki, reconstruction plans were underway along with the building of a new shopping center and the governor who was a fellow high school classmate of Konno’s opened up a branch shop for Konno there. At the end of 2015 on a corner of the shopping center they opened a showroom which doubles as a store. As a symbol of reconstruction, the Damborghini continues to garner ever more attention as a main draw of Onagawa.

It was the first time for Konno to setup and operate a retail store. However, he had originally developed furniture and other ideas for goods for the general public. The customers loved the corrugated cardboard dinosaurs, insects, and revolvers. Through the use of a processing machine bought for 20 million yen their laser art gifts quickly sold out.

The Damborghini was the expanding contact point between the people and the city. A small step was taken in contribution towards local revitalization.

Fans driving actual Lamborghini’s made collaboration with Damborghini a reality. However, comparing the creation next to the actual car, the differences weighed on his mind. So, Konno reviewed the details of each part of the car and decided to begin creating his second car raising the bar for quality and detail. Taking the possibilities corrugated cardboard offers and pushing them to the limits, after 1 year in 2016 they unveiled the born again Damborghini! Their one hope is for all who see their creation to take to heart the commitment to detail and the love it expresses for their reviving hometown.

ついに明日5月28日(日)から女川町で一般公開が始まります!!。 強化ダンボール製の『AT-ACT』です!!。 ここでにおわせていたハナシw ht [...]

自分なりの答え・・・いま思えば目の前にあったそれは当初から言葉に出していたもの、そのものだったのかと思います…。 『ダンボルギーニ』への道もそこに至る俺の想いなども書いてきましたが、これなくしては語 [...]

2015年11月からさかのぼることちょうど一年前… スタッフA:「社長!、1/1が完成したらどこに置くんですか?。」 俺:「女川のテナントもどうするか決まってないから、倉庫代わりに店内に展示す [...]

さて、2015年11月5日…仙台の夢メッセで行われたビジネスマッチングイベントで 『ダンボルギーニ』(1号機) 初公開!!!!! ・・・「よっしゃあああああ!!!!!」 [...]